Sandbox:Sneakyranger2

Foreword

To every action, there is always opposed an equal reaction; or, the mutual actions of two bodies upon each other are always equal, and directed to contrary parts.

So you're new, no one else has joined engineering, the bridge needs thrust, and you have no idea how to set up the thrusters? Skip to here.

It should be noted that it is not required for you to read this entire page before you get started with thrusters. Much of the guide has been written to serve as reference material as you progress on your journey, especially the advanced guide. However, if you’re a new Atmospheric Technician, it’s definitely advised to read through the basic guide in its entirety.

Generally, only atmospheric technicians should be expected to know how to utilize the burn chamber, as the thrusters are their responsibility. Regular Engineers should never be held to the same standard as atmos techs in regards to thrusters, and can't be relied on to do anything advanced. Remember, regular engineers should really only be setting up the thrusters in the absence of an atmos tech, and even then they're only expected to do a simple cold phoron setup.

Basic Guide

Overview

To best understand what you're doing, it is important to know how thrusters function. Luckily, this is not too hard.

Whenever someone on the bridge presses a movement button, the thruster nodules (the things sticking out the back of the ship that look like rocket engines) shoot out a bit of whatever gas is inside them and their connected pipe network. The type of gas and its pressure affect how much the ship accelerates each time a movement button is pressed. Any gas in the thruster will move the ship a little bit, but the higher the pressure, the faster the gas shoots out. The higher the molar mass, the more force you provide to move in the direction you want.

As far as molar mass goes, it's all about equal and opposite reactions. A good way to illustrate this is to the difference between throwing a small item, like a pen, and a larger item, like a crowbar, when the ship gravity goes out. Obviously, throwing the crowbar will move you more in the opposite direction from where you threw it.

For pressure, it's important to remember that (for our purposes) pressure refers to the force that a gas exerts on its container from the inside. This means that when an opening is made in a container, the pressure is proportional to how much force the gas escapes the container with. With the increase in force comes an increase in thrust per burn.

If that's too difficult to understand right away, you can get a basic idea of gas pressure by thinking of a big balloon: when you blow up a balloon very full and let it go, it at first moves quite quickly and steadily slows down as the pressure inside it diminishes.

To get back to the point, mass is the larger factor in thrust. Therefore, gases with higher molar masses are essential (hence the frequent use of phoron with its chunky molar mass). As for pressure, the unmodified thruster design allows for a maximum thruster line pressure of 15,000kPa. Whenever the thrusters are fired, some gas is expelled from the thrusters resulting in acceleration for the ship and a decrease of thruster line pressure as some gas escapes.

Layout

Fuel and oxygen are moved from large tanks in Engineering Air Mixing through mixing equipment in the nacelles and finally into the burn chambers through fuel supply lines. Starboard and Port thrusters have separate phoron and hydrogen supply lines from each other, though they share the same oxygen supply line.

Each thruster also has an airlock to the exterior. Both thrusters are found in the aft of deck one, and are identical in layout. Starboard Propulsion can be entered directly through maintenance by all of engineering. Port Propulsion must be accessed through a segment of atmospherics called Air Mixing. Unlike the rest of atmospherics, regular engineers have access to this area through maintenance near the living quarters lift.

The far ends of the starboard and port wing frames on deck two each have a maneuvering thruster, as well. They are very low power (together offer only 0.05 gm/h acceleration per burn) but only require power to operate. You won’t ever have to worry about touching these, but it’s good to know they’re there.

Below, you can see a color coded map of a nacelle and the important things inside it.

- Fuel Supply Monitors: One for phoron, one for hydrogen, these consoles allow you to pressurize a thuster’s phoron/hydrogen supply lines (purple/red pipes) anywhere up to 15,000kPa. The gas is drawn directly from their respective 3x3 storage tanks through vents, which act like pumps. (This means there is no backflow into the tank)

- Atmosphere Monitoring Console: This console provides live readouts of the combustion chamber’s pressure, temperature, and gas composition, as well as allowing you to fully control both the chamber’s input and output.

- Ignition Switch: Exactly what it sounds like. Pressing this will strike a spark in the combustion chamber, igniting any gases if possible.

- Fuel Mixer: Creates your fuel mix for the combustion chamber. You may set any ratio of phoron/hydrogen/oxygen you wish here. Draws phoron from the north purple pipe, hydrogen from the west red pipe, and oxygen from the south cyan pipe.

- Mixer Fuel Pumps: One for phoron, one for hydrogen, these pumps draw from their respective supply lines and control the mixer’s access to these fuels. They start offline.

- Mixer Oxygen Regulator: Best to leave untouched. Controls the mixer’s oxygen supply, and is automatically set to 15,000kPa. Takes its input directly from the output of the Oxygen Supply Tank in Atmospherics.

- Chamber Fuel Injector: Acts as the chamber’s input. The injector pumps fresh fuel mix into the combustion chamber to be burned at a rate of up to 700 L/s. Unlike most devices, the injector has no pressurization limit, but its effectiveness will still be significantly impacted by any large difference between input and output pressures.

- Chamber Vents: Acts as the chamber’s output. These three vents draw gas from the chamber at a rate of up to 200 L/s each, and can pressurize their connected pipeline up to 15,000kPa. It’s important to note that these vents only pump gas to the thruster pumps, not directly into the thruster line.

- Exterior Blast Door: In any emergencies involving a fiery death in propulsion, this is your best friend. Opening the exterior blast doors will vent the chamber very quickly.

- Thruster Pump/Regulator: These are what actually allow the heated burn mix into the thruster line itself. They draw from the output of the chamber’s vents.

- Phoron Bypass Regulator: Allows flow of phoron from the phoron supply line directly into the thruster line itself, if desired.

- Thrusters: Vroom-vroom. Thrusters are what make the ship go. They act as 200 L containers, open to their connected pipe network (the thruster line). There’s no way to physically interact with these except to destroy them, and they cannot be rebuilt or replaced in-game. Don’t lose them!

Methods

Cold Setup

The cold gas setup propels the ship by expelling pure, cold (20C) phoron out the thrusters. This setup is by far the quickest and simplest there is, and provides considerable thrust. This makes it a very appealing option for those who don’t care to spend much time or effort on thrusters, and should be your main go-to if you’re just a regular engineer.

These steps should be performed on both the starboard and port thrusters for full effect:

- Set target output pressure on Phoron Supply Monitor to 15,000 kPa.

- Set Phoron Bypass Regulator target pressure to 15,000 kPa, and toggle valve to “Unlocked”.

That’s it, really. If done correctly, you will see the meter in front of the pressure regulator begin to fill up to 15,000 kPa.

It's worth noting that this is the least fuel efficient method of propelling the ship, but if the SCC didn't want you doing it, it wouldn't be the recommended basic option. Despite the inefficiency, this setup can provide more thrust than a standard hot gas setup ever possibly could, providing the ship with an acceleration of ~1.34 Gm/h per burn when the thrusters are filled to 15,000 kPa.

Hot Setup

The hot gas setup propels the ship by igniting a fuel rich mixture of phoron and oxygen which is then pumped into and expelled out of the thrusters. This typically produces superheated phoron and CO2, which provides ample pressure just from the high temperatures. Contrary to intuition, this setup does not produce more thrust than the cold gas setup, but it does make a much more efficient use of phoron. Why is covered here in depth.

These steps should be performed on both the starboard and port thrusters for full effect:

- (Optional) In Atmospherics just outside of Port Propulsion, set the max output pressure on the Oxygen Supply Monitor to 15,000kPa. This will help speed up fuel mixing.

- Set the max output pressure on the Phoron Supply Monitor to 15,000kPa.

- Open the Fuel Mixer, click configure, then click on the green button next to the port corresponding to the red pipeline. This will disconnect the Hydrogen line from the mixer, as it will not be used here. Leave the ratios kept at 80% North (Phoron), and 20% South (Oxygen). Once done, turn the Fuel Mixer back on.

- Turn on the Mixer Phoron Pump just to the north of the mixer, and MAX its target pressure to 15,000kPa. Fuel mix should start filling the Chamber Fuel Injector line now.

- On the Atmosphere Monitoring Console, set input flow rate limit to 700 L/s and toggle power to “Injecting”. You should now see the chamber filling up with fuel mix on the console readout.

- Once the chamber reaches 500-1,000kPa, hit the Ignition Switch.

- Watch the Atmosphere Monitoring Console. Once the temperature has stopped increasing dramatically, and O2 composition is ~2-3%, you can now toggle the chamber output ON. Set the target output pressure to 15,000kPa.

- Turn the Thruster Pump/Regulator on and MAX their target pressure to 15,000kPa.

If done correctly, you should see the meter in front of the thruster pump/regulator begin filling.

It is strongly advised to keep an eye on the phoron supply, as leaving this setup to mix and inject new fuel mix indefinitely can and will empty the entire phoron tank into the combustion chambers. Once in the chamber, this phoron cannot feasibly be retrieved. A good time to shut off a thruster's Phoron Supply Monitor's output would be when the chamber pressure approaches 12,000 kPa - 15,000 kPa after ignition.

Emergency Procedure

Oh no, that damn meddling apprentice somehow totally screwed the thrusters, and everything is on fire! Oh, the humanity! Grab your voidsuit, some inflatables, and prepare to die a fiery death!

Most thruster accidents involve a rather hot phoron fire, or the superheated leftovers of one. Atmos voidsuits can handle up to 40,000 Kelvin, but regular engineering voidsuits can’t withstand more than 5,000 Kelvin, which some thruster fires can surpass. This means that unless you’re an atmos tech, you may need to act quickly once inside. For that reason, it’s advised that you check the damages on camera before approaching, and have a plan beforehand. Remember to check emergency shutter readings, too!

Luckily, most thruster related catastrophes can be handled with a quick two-step plan! TURN OFF CHAMBER INJECTION. If it’s off, leave it. The only thing that can sustain long lasting thruster room fires is the injection of new fuel mix through the combustion chamber. In the likely case of the chamber walls melting, the thruster room will be acting as part of the chamber. VENT THE AFFECTED AREA. If the chamber walls have melted, or if the problem is otherwise related to the chamber, simply OPEN THE EXTERIOR BLAST DOOR. Otherwise, pry out some floor plating, or force open the thruster airlock. Don’t forget your magboots, or Sir Isaac Newton might be sweeping you off your feet.

Afterword

If you know the above, congratulations! You have the basic certifications of an atmospheric technician. There's more to learn, of course, but most players can stop here. Even if you do want to go further, though, remember that experimentation is half the fun of atmospherics. Still want more? If you're certain you're ready, then go on to the advanced guide.

Advanced Guide

This section of the guide is for those who want to take a much deeper dive into thrusters or wish for a better understanding of everything that’s going on behind the scenes. The concepts covered from here on are NOT at all required to be understood for most thruster operations, but can be useful if you intend to experiment with thrusters. It is mostly included for reference, but it can fast track you to advanced thruster knowledge without having to do some painstaking code dives and experiments on your own.

This section of the guide is, to tell the truth, a lot. Don’t let that discourage you if you have a particular interest in thrusters. You don’t need to know everything here to start experimenting with thrusters, but the more you know, the better you’ll know how to approach them in your own shenanigans. Always remember, even failed thruster experiments are good so long as you learned something from it. Just try not to blow up the ship in the process!

Again, this is advanced material. Do not discourage yourself if you can't learn everything at once.

Thrusters

Thrusters and Thruster Lines

While not always identical in sprite, all thrusters are mechanically identical. Thrusters are 200 L containers which act as part of the network they’re attached to. This means that the pressure in the thrusters will always be the same as the pressure in the thruster line. When a thruster is fired, it expels 15 L from that container, multiplied by the engine’s thrust limiter modifier (0-1). By default, thrust limiters are set to 100%, corresponding to a value of 1. It’s the gas inside the expelled portion that ultimately determines the thrust.

The thruster line itself can have a significant impact on the performance of the thrusters. The larger the thruster line, the larger the volume of the thruster network. A larger volume network takes more burns to drain to a certain pressure than a smaller volume network, allowing the thruster line to better maintain higher pressures throughout extended use even if no new gas is being pumped in. Likewise, it takes more time to pump a larger network to those higher pressures.

Ideal Thrust

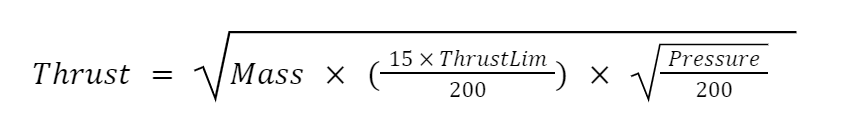

As mentioned earlier, thrust is determined by the mass and pressure of the propellant. For ideal thrust, we want to maximize both factors. Mass is the larger factor here, by no small margin. To be precise, let’s look at the thrust equation. This equation allows you to calculate the thrust given by a single thruster when provided the propellant mass and pressure within the thruster.

Mass: Total mass in the 200 L container of the thruster, not the mass used per burn. Can be found by solving for moles with the Ideal Gas Law, and multiplying by molar mass of gas (make sure to account for gas composition). Measured in kg.

Pressure: Pressure in the thruster, measured in kPa. (Remember that 1 MPa = 1000 kPa)

ThrustLim: Thrust limiter setting. The bridge controls this from the engine consoles on a range from 0% - 100%, corresponding to values of 0 - 1. Set to 100% by default.

The molar mass of your propellant is crucial to how much thrust you get. Just to compare the gases you might see in the thrusters, the molar mass of phoron is about 10x that of CO2, and 200x that of hydrogen. Ship mass affects how much force it needs to move and is a coded variable. Most ships and shuttles can get by with just CO2, but for a ship as massive as the Horizon, phoron is a necessity for moving at any reasonable pace.

As can be seen in the thrust equation, pressure is a relatively insignificant factor compared to mass. This isn’t to say it's not relevant, however. With a combustion chamber at our disposal, achieving incredibly high pressures is almost trivial. Unfortunately, our ability to utilize that benefit is severely limited by other equipment.

The Pressure Limitation

No matter what pressure the combustion chamber might reach, all the devices we use in moving gas to the thruster line can only pressurize any given network to 15,000kPa at maximum. This includes any gas pump, as well as the vents that pull gas from the combustion chamber and phoron supply tank. The only notable exceptions are gas mixers and filters, but they also tend to struggle past 15,000kPa.

It’s very important to recognize how you reached that 15,000kPa point. In a fixed volume environment such as the thrusters, pressure can be raised in two ways. One, force more gas in. Two, increase the temperature of the gas.

So, what does this mean? Why is this so important?

It means that a hot molecule of any given gas will always produce more thrust than a cold one of the same type due to its higher pressure. However, between two pipelines of identical pressure, the cold one will have a higher density of gas due to most of its pressure coming from the quantity of gas, not temperature. Recall the significance of mass in determining thrust. Since we can ensure that the thrusters can always reach 15,000kPa regardless of setup, using cold gas will always provide higher levels of thrust than hot gas of the same type, though suffering in fuel efficiency.

This doesn’t mean that high temperatures are eternally doomed to provide low thrust, however. There are ways to modify the thrusters to bypass the normal pressure limitations and allow for both high mass density and high pressures.

Combustion and Gasses

Whilst the happenings of the combustion chamber are rather self evident, it can still help to take a closer look at precisely what’s going on in there.

Fuel and Oxidizers

Much like in real life, combustion on Aurora follows the combustion triangle, meaning you require heat, fuel, and oxidizer for a fire. However, for better or worse, the similarities end there.

Contrary to all known laws of science and common sense, all combustion produces CO2 exclusively. It doesn’t matter what combination of fuel and oxidizer you have, you will always get CO2 as a result. It doesn’t make any sense, but that’s just how it works here.

Fuels

![]() Phoron (Ph). Has a molar heat capacity value of 200, and a molar mass of 0.405 kg/mol.

Phoron (Ph). Has a molar heat capacity value of 200, and a molar mass of 0.405 kg/mol.

![]() Hydrogen (H2). Has a molar heat capacity value of 100, and a molar mass of 0.002 kg/mol.

Hydrogen (H2). Has a molar heat capacity value of 100, and a molar mass of 0.002 kg/mol.

Oxidizers

![]() Oxygen (O2). Has a molar heat capacity value of 20, and a molar mass of 0.032 kg/mol.

Oxygen (O2). Has a molar heat capacity value of 20, and a molar mass of 0.032 kg/mol.

![]() Nitrous Oxide (N2O). Has a molar heat capacity value of 40, and a molar mass of 0.044 kg/mol.

Nitrous Oxide (N2O). Has a molar heat capacity value of 40, and a molar mass of 0.044 kg/mol.

Products

![]() Carbon Dioxide (CO2). Has a molar heat capacity value of 30, and a molar mass of 0.044 kg/mol.

Carbon Dioxide (CO2). Has a molar heat capacity value of 30, and a molar mass of 0.044 kg/mol.

Burn Ratio

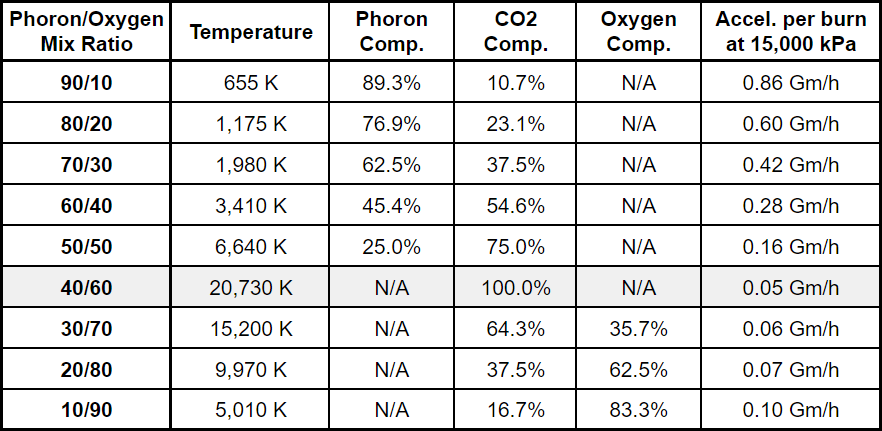

Similarly, the stoichiometric fuel-oxidizer ratio is the same between all gases. Burning a mixture of 40% fuel to 60% oxidizer will always use up all components, leaving behind pure CO2. This means that burning any mixture with more than 40% fuel will result in extra fuel left over while burning any mixture with more than 60% oxidizer will result in extra oxidizer left over.

The basic equation goes like this:

The farther you are from the 40/60 ratio, the more extra oxidizer or fuel you’ll have, as well as a lower temperature combustion. To better display this relationship, this collapsible has a table of the results of some phoron-oxygen burns at several different ratios.

Combustion

There are a couple more aspects to combustion that are rarely seen or touched, but are worth covering as they have plenty of potential for more creative projects.

The temperature that a combustion reaches depends strictly on the fuel-oxidizer ratio, as well as the combustion component’s temperature and molar heat capacity. What this means is that if you preheat the fuel or oxidizer beforehand, you can reach higher temperatures than are possible with regular 20C components. Otherwise, the final temperature for a given fuel-oxidizer mix will always be the same. It should be noted that the quantity of fuel mix has no importance here.

This also ties into flash points. You don’t always need a spark to cause combustion. If there’s already enough heat, combustion will occur spontaneously. This can occur not just within the combustion chamber, but also within closed systems such as pipes and canisters.

Autoignition temperature for all mixtures is 125C.

Combustion Chamber Handling

The combustion chamber walls are tough, but reinforced plastitanium alloy isn’t indestructible. When exposed to flames at 6,000 K or higher, the chamber walls start to take damage. They aren’t quick to melt, but they will eventually.

So, how do you keep from turning the thruster room into the sector’s largest bonfire? There’s two ways.

The first is to simply make sure that your fuel mixer isn’t creating too hot of a mix. As a general rule of thumb, the higher the oxygen concentration, the hotter the burn. The highest concentration of oxygen you can have in your burn mix without burning hotter than 6,000 K depends on what fuel you're using. For phoron, it's 48% O2. For hydrogen, it's 41% O2.

The second way is to simply turn off the injection once the combustion starts. Without new fuel mix being injected, the combustion will run out of either fuel or oxidizer and simmer out. Both flame and sufficient temperature is required to melt the chamber walls, so the superheated gas alone is safe to hold.

Additionally, for the sake of efficiency, it can sometimes be beneficial to fill the chamber with a large amount of cold burn mix before ignition rather than ignite almost immediately. This is because pump performance dramatically suffers when pumping lower pressures to higher pressures. When you ignite a burn mix, the pressure will rapidly shoot up and make any further injection of fresh burn mix much slower.

Modifications and Experimentation

Foreword

Well done for making it this far; at some point you probably began wondering what the practical application of all this knowledge was. This section is dedicated to covering that, with a caveat: It's not here to give you all the answers. Part of the fun of atmospherics is testing and putting things together in different ways, and if a wiki guide were to tell you how to do 99% of every advanced setup you'd want to do, then a lot of the fun would be lost.

However, it's also no fun to be left in the dark, so this section collects some general ideas on what you could do without getting in to too many specifics.

First things first, though: it is strongly advised to perform any pipe related modifications before the pipes are filled. When you unwrench a pipe segment, the contents of that particular segment are released into the air. If a pipe is full of phoron, that can be a problem. There are some exceptions; notable pieces of equipment that are safe to remove at any time include pumps, regulators, valves, and connectors.

If you’re experimenting with thrusters, try to be mindful of the ship's needs as well. Experimentation tends to be a large time commitment, and the bridge typically won’t want to wait the whole round for thrust. If you’re delving into uncharted territory, you might want to set one side of the ship up with a cold setup while you focus on messing with the other side. Otherwise, if you already have a solid idea on what you’re trying to do, great! Go get ‘em, champ.

Improved Gas Flow

The simplest kind of modification you can make to the thrusters. The flow from the combustion chamber to the thruster line itself is bottlenecked by the Thruster Pump/Regulator. The regulator itself isn’t very useful here, as it can’t work as a pump. Maybe you could find some way to increase efficiency.

Increased Thruster Line Volume

Another simple modification. While it’s not as useful as it once was now that Chamber Vents can output at 15,000kPa instead of 5,000kPa, it can sometimes be beneficial to increase the volume of the thruster line to make it easier for thrusters to maintain higher or more stable pressures during extended use. There are plenty of ways to do this - use your imagination.

CO2 Filtering

This is more of an intermediate modification. The idea is to simply filter out the CO2 from the thruster line, leaving you with a line of pure phoron. How you handle that superheated CO2 is where you have to get a little creative. The main thing you'll want to be mindful of is to make sure the filtering process doesn't clog up the flow to the thrusters too much, or you may have difficulty sustaining any reasonable pressure throughout extended use.

Heat Exchangers

Heat exchanger related designs are on the advanced end of modifications, and as such are one of the more difficult but productive modifications to tackle.

Heat exchangers are devices that equalize temperatures between two networks or systems without allowing their contents to mix together. They come in two forms:

- Heat Exchangers: Also known as heat exchanger plates. In order to operate, a pair of these must be wrenched down facing each other. Each has an end for a pipeline to merge into. The attached pipe networks will automatically exchange heat with each other until their temperature equalizes.

- Heat Exchange Pipes: Also known as radiators. These act just like regular pipes in terms of flow. Instead of equalizing two pipelines, these equalize the temperature of the pipe’s contents with the surrounding air. Essentially, heat transfer between an open and closed environment.

As for heat exchangers, recall above the discussion on the relationship between heat and pressure under The Pressure Limitation, and some ideas might jump in to your head.

Checking Your Work

If you plan to experiment with your own designs, it’s important to be able to measure your work and compare it to your other efforts to see if you’ve made an improvement, or if you’ve messed up in some way.

Besides keeping a close eye on your pipes with a gas analyzer, the best way to check your work is to confer with the bridge. Ask for a thrust and acceleration reading! Simply ask them to turn on the thrusters for a minute, and take a look at the acceleration on a navigation console or ask them for it yourself.

Note that if the bridge reports an acceleration of 1.0 Gm/h, it’s likely to be more in reality, as the helm’s default acceleration limiter is set to 1.0 gm/h. Furthermore, they'll likely try to tell you total thrust, propellant mass, etc. from the engine console; this information is worthless to you as you can already calculate most of that from the thruster bay. Insist upon the acceleration value if you want an accurate measurement.

If you’ve been working on just a single set of thrusters, you might want to ask the bridge to turn on/off specific thrusters to get the readings you want.

Engineering Department

| |

| Head of Department | Chief Engineer |

| Personnel | Engineer - Atmospheric Technician |

| Useful Guides | Guide to Atmospherics - Supermatter Engine - Guide to the INDRA - Turbine Engine - Guide to Thrusters - Telecommunications - Integrated Electronics |