Difference between revisions of "Sandbox:CombustionEngine"

(Sandbox for Guide to Combustion Engine or some similar title. We are not porting the paradise guide as I do not feel as though it will fit our wiki.) |

|||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:Turbine_location.png|thumbnail|480px|The turbine is hidden in maintenance just east of atmospherics.]] | |||

The Combustion Turbine, sometimes called the Combustion Engine or just Turbine, is a small power unit utilizing flammable gasses to spin a turbine. Due to the low power output, the turbine is typically used as the primary power source for small vessels, or as an auxiliary power unit on larger vessels such as the [[SCCV Horizon]]. As such, it is never recommended to operate the Horizon solely off of the turbine, instead the [[Supermatter Reactor]] or [[INDRA]] should be used. | |||

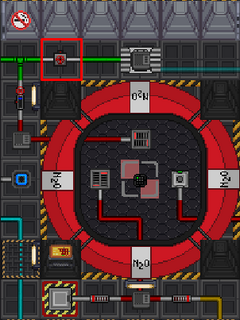

Turbines fitted onto small vessels are typically found within the engineering section as the central power source. On the Horizon, the turbine is found in Deck 1 Maintenance just east of atmospherics. | |||

==Turbine Operation== | |||

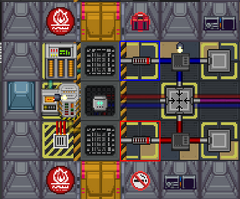

The turbine is easy to start and operate while leaving opportunity to tweak the set-up for a preferred (or cost effective) operation. Below is the start-up process for the SCCV Horizon. The same principle applies to off-ship vessels, however certain components, such as the gas mixer or pumps, may not be in the same location. Most pumps should be labeled to ease these differences. [[File:Turbine_pumps.png|thumbnail|240px|The connector to cold loop pump is squared in blue. The cooling array to turbine pump is squared in red.]] | |||

*Attach a hydrogen (H2) gas canister to the cold loop connector. | |||

**Unlike the burn chamber, the cold loop is not attached to the Horizon's atmospheric storage. Gas canisters must be used to fill the cold loop. | |||

*Enable the connector to cold loop pump, and the cooling array to turbine pump. This will begin circulation of the cold loop. | |||

*Configure the gas mixer to output east and inject hydrogen and oxygen at the pre-set ratio of 60% oxygen and 40% hydrogen.[[File:Turbine_oxidant_valve.png|thumbnail|240px|Just north of the N2O tank is the valve that allows the oxidant (O2/N2O) into the turbine.]] [[File:Turbine_atmos_pumps.png|thumbnail|240px|The oxidant to turbine pump is squared in blue and connects to the N2O and O2 tanks. The hydrogen to turbine pump squared in red connects to the hydrogen tank.]] | |||

**Off-ships will require the use of gas canisters to fill the burn chamber. The Horizon can inject gas from the storage tanks within atmospherics. This requires the use of two pumps, and the activation of a valve shown to the right. | |||

***'''Note:''' By opening this valve, the burn chambers will be using the same oxidant as the thrusters. | |||

*Enable the gas mixer until the desired amount of burn mix has been injected into the burn chamber. | |||

*'''Disable the gas mixer! Do not leave injection on!''' | |||

*Ignite the burn mix inside the burn chamber and wait for it to fully burn out. | |||

**On off-ship vessels, some strain on the burn chamber glass at this step is expected. | |||

*Once the fire has stopped and the contents of the tank are 100% CO2, enable hot loop circulation via the Turbine Hot Loop Control console: The recommend configuration is 700L/s input and 1000kpa output. | |||

**The higher you put the output, the more power it generates. Raise as necessary. Keep in mind that this will also lead to the burn chamber cooling down faster. | |||

'''WARNING:''' If you feel the burn mixture is going to break the glass or the burn chamber walls, lower the blast doors and vent the chamber immediately! Off-ship vessels have a portable generator in the back if the turbine runs out of fuel, or another mishap occurs. | |||

==Turbine Design== | |||

While the layout of the turbine may change from ship to ship, the basic concept remains the same. A turbine is made up of X parts: Burn chamber, hot loop, cold loop, cooling array, TEG, connectors. | |||

The '''burn chamber''' is, as you might expect, where the burn mixture is ignited to produce useable fuel. This chamber can vary in size but requires a few basic elements. It needs an injector to inject the burn mixture into the chamber, a vent to bring the hot fuel into the hot loop, a second injector to cycle back the hot loop gas, and blast doors for emergency venting. Some burn chambers may have glass viewing ports, but they're not inherently required. Often times, a sensor is present to display temperature, mixture contents, and chamber pressure to a console on the user. | |||

The '''hot loop''' is where the fuel is help from the burn chamber. This loop exits the burn chamber, enters into one of the inlet ports on the TEG, exits out the exhaust port of the TEG, and re-injects into the burn chamber. The ports on the TEG must be across from each other or else the cold and hot loops would be mixed and remove the heat imbalance that causes the TEG to function. Beware that this loop by its nature operates at much higher temperatures and pressures than any other loop and is the most likely to fail if the pressure is too high. If the temperature and pressure become too high, open the '''emergency cold loop to hot loop valves'''. This will instantly lower the temperature in the hot loop and open it to the cooling array. '''This will stop most power production from the turbine.''' | |||

The '''cold loop''' is, as expected, where the cold gas is. Much like the hot loop, it connects to an inlet and exhaust port on the TEG. They must be across from each other. Unlike the hot loop, the cold loop connects to the cooling array. This allows the heat transferred into the cold loop from the hot loop to be emitted into space, which reduces the temperature of the cold loop gas, and increases the heat transfer in the TEG. | |||

The '''cooling array''' is similar to the Supermatter Reactor's cooling array. It is a loop of pipes that radiate heat into space and reduce the temperature of the gases within its pipes. Unlike normal pipes, which mechanically act like insulated piping, cooling pipes have a much higher surface area and no insulation, allowing for greater heat removal. | |||

The '''thermoelectric generator (TEG)''' is the machine that converts heat in gases to electricity. Rather than operating via high-pressure steam turning an internal turbine, the TEG works through heat transfer between two gas loops. The greater the heat difference, the more electricity produced. It is the exact same machine utilized by the Supermatter Reactor. | |||

'''Connectors''' are the ways in which gas is introduced into the turbine system. The Horizon, uniquely, has a direct connection between the burn chamber and its gas storage, however other vessels must use gas canisters to inject fuel into the system, or gas into the cold loop. The burn chamber connectors require an omnimixer to achieve a proper ratio of oxidant to hydrogen. The cold loop, however, does not require any particular mixture. | |||

==Turbine Theory== | |||

<small>''See also: [[Guide to Atmospherics]]''</small> | |||

At a fundamental level, the turbine engine is simply what happens when you combine the combustion chamber of the thrusters and attach it to a TEG from the Supermatter engine. This gives us a look into how it works and lessens the legwork for describing the theory of how this engine works. | |||

The simplified process is this: <code>Burn a gas mixture to produce superheated CO2 -> circulate CO2 in hot loop -> circulate cold gas in the cold loop -> temperature difference between hot/cold loops generates voltage in TEG</code> | |||

But first, there is something key to understand. The Turbine engine is not, by technicality, a turbine generator. Turbine generators work through pushing high-pressure fluid through turbine fan blades causing rotary motion and driving a generator unit. The TEGs do not operate (entirely) off of this principle. They operate using temperature differences between two ends of the generator. Through the Seebeck effect (which is NOT modeled in the mechanics), voltage is generated. Now, the TEGs mechanically are a black box in terms of power generation. What this tells us, however, is how the turbine works. | |||

===The Hot Loop=== | |||

<small>''See also: [[Guide_to_Thrusters#Combustion_and_Gasses|Guide to Thrusters/Combustion and Gasses]]''</small> | |||

Much like the thrusters, the turbine generator operates via combustion. The thrusters use this to increase pressure to generator more force when pushed out of the thruster banks. Meanwhile, the turbine uses combustion to superheat gas for the aforementioned temperature difference. The end effect for both systems is the same. The limiting factor is the pressure chokepoints in the system, typically at vents, pumps, and valves. Given pressure is directly proportional to temperature, the turbine similarly wants higher pressures in the system. | |||

So, what do we need for combustion? Fuel, oxygen, and heat. Heat is easy. The igniter provides the initial heat, and the rest is maintained by the combustion itself. Below are the fuels and oxidizers available on the Horizon. | |||

'''Fuels''' | |||

[[File:Phoron_canister.png]] '''Phoron (Ph)'''. Has a molar heat capacity value of 200, and a molar mass of 0.405 kg/mol.<br> | |||

[[File:Hydrogen_canister.png]] '''Hydrogen (H2)'''. Has a molar heat capacity value of 100, and a molar mass of 0.002 kg/mol. | |||

'''Oxidizers''' | |||

[[File:Oxygen_canister.png]] '''Oxygen (O2)'''. Has a molar heat capacity value of 20, and a molar mass of 0.032 kg/mol.<br> | |||

[[File:Nitrous_canister.png]] '''Nitrous Oxide (N2O)'''. Has a molar heat capacity value of 40, and a molar mass of 0.044 kg/mol. | |||

'''Products''' | |||

[[File:Carbon_canister.png]] '''Carbon Dioxide (CO2)'''. Has a molar heat capacity value of 30, and a molar mass of 0.044 kg/mol. | |||

The choice in fuels and oxidizers largely boils down to choosing between phoron and hydrogen. Phoron will burn hotter than hydrogen. This is as a result of its heat capacity; how much heat energy it can store before the temperature raises. Phoron, then is a much better fuel than hydrogen. The issue, however, is phoron is rare and VERY expensive. It's recommended to stick with hydrogen for burn mixes. | |||

Oxidizers, in this case, work practically the same. There may be some minor variations in performance. Their goal is entirely to produce oxygen for the combustion process. Finally, we have the product: Carbon dioxide. Regardless of what components are used in combustion, the result is '''always''' CO2. This is a fact of the game mechanics, even if it is scientifically dubious. Thankfully, the temperature of CO2 is all that matters in this system. The hotter the combustion burned, the higher the CO2 temperature, the more performance from the TEG. | |||

Earlier in the process, a ration was mentioned. 40% fuel to 60% Oxidant. This is, essentially, the golden ratio in combustion that leaves no fuel or oxidants remaining. There is a lot of math behind this ratio, and further details on the numbers behind each ratio increment, that can be found on the [[Guide_to_Thrusters#Burn_Ratio|Thrusters guide here]]. The short version is that the 40%/60% ratio maximizes the burn temperature, leaves no fuel or oxidants remaining, and is the most efficient ratio available. Seeing as we care mostly about the temperature of the system, this ratio is best left as it is. | |||

There is a safety note remember about this whole process. Walls and glass only begin to take damage and melt if there is '''heat and fire'''. If there is no fire, the walls and windows take no damage. This leaves us with two options: Burn a less efficient mixture to remain below the 6000K limit of the walls or prevent the combustion process from continuing. This is why it is mentioned to turn off the injectors before firing the combustion chamber. The burn mix will combust, all of the oxidizers and fuel will be consumed, the fire will die out, and we are left with a superheated gas as a result. In theory, a less efficient mixture can be used, and the combustion process can continue as long as desired. | |||

===The Cold Loop=== | |||

<small>''See also: [[Supermatter_Reactor#Coolant|Supermatter Reactor/Coolant]]''</small> | |||

The cold loop is a much simpler system compared to the hot loop. It is made of 2 components: coolant gas and cooling array. The only major question here, then, is the heat capacity of the gas being used. Since temperature difference is what drives the TEG to operate, we want to reduce the increases in the temperature of the cold loop as much as possible. The higher the heat capacity, the better the cold loop performance. This is simply due to heat capacity's function in a gas. The more capacity the gas has, the more heat energy it can absorb before raising in temperature. Once it meets its heat capacity, it rises in temperature. For this reason, the cold loop shares the same fuel options with the hot loop: Phoron and hydrogen. | |||

The only other major item of note is the cooling array. This is the best passive method to reduce the temperature in the loop. The longer the cooling array, the better the cold loop performance. There are other methods of reducing the loop's temperature, such as gas cooler. These, however, consume power. Add too many coolers, and it will consume all of the power being produced by the system. | |||

===Improvement=== | |||

<small>''See also: [[Guide_to_Thrusters#Modifications_and_Experimentation|Guide to Thrusters/Modifications and Experimentation]]''</small> | |||

The turbine is a relatively limited engine model. It functions reliably, and produces consistent power, but it is limited by the same metrics as the Supermatter reactor AND the thrusters. However, this also gives us a view into where the turbine can improve. The less obvious area is cooling. The cold loop will naturally rise in temperature over time, so improving the cooling method of the system, or raising the heat capacity of the loop, is a simple method to improving engine performance. | |||

The more obvious area of improvement is system pressure. Much like the thrusters, every connection and fixture on a pipe network has limiting pressure. This maximum is 15000 KPa across all fixtures, whether they be pumps or vents. Similarly to the thrusters, there are ways around these limitations. You can find more details on that [[Guide_to_Thrusters#Modifications_and_Experimentation|here]]. | |||

'''Note:''' This guide does not go into the gritty details of each process and concept. The turbine is, at its essence, the combination of 2 pre-existing systems which have far more details and math present on their respective pages. For brevity purposes, those pages are linked. It is highly recommended to read the links above if you wish to know more behind the atmospheric systems. | |||

Latest revision as of 23:00, 10 January 2025

The Combustion Turbine, sometimes called the Combustion Engine or just Turbine, is a small power unit utilizing flammable gasses to spin a turbine. Due to the low power output, the turbine is typically used as the primary power source for small vessels, or as an auxiliary power unit on larger vessels such as the SCCV Horizon. As such, it is never recommended to operate the Horizon solely off of the turbine, instead the Supermatter Reactor or INDRA should be used.

Turbines fitted onto small vessels are typically found within the engineering section as the central power source. On the Horizon, the turbine is found in Deck 1 Maintenance just east of atmospherics.

Turbine Operation

The turbine is easy to start and operate while leaving opportunity to tweak the set-up for a preferred (or cost effective) operation. Below is the start-up process for the SCCV Horizon. The same principle applies to off-ship vessels, however certain components, such as the gas mixer or pumps, may not be in the same location. Most pumps should be labeled to ease these differences.

- Attach a hydrogen (H2) gas canister to the cold loop connector.

- Unlike the burn chamber, the cold loop is not attached to the Horizon's atmospheric storage. Gas canisters must be used to fill the cold loop.

- Enable the connector to cold loop pump, and the cooling array to turbine pump. This will begin circulation of the cold loop.

- Configure the gas mixer to output east and inject hydrogen and oxygen at the pre-set ratio of 60% oxygen and 40% hydrogen.

- Off-ships will require the use of gas canisters to fill the burn chamber. The Horizon can inject gas from the storage tanks within atmospherics. This requires the use of two pumps, and the activation of a valve shown to the right.

- Note: By opening this valve, the burn chambers will be using the same oxidant as the thrusters.

- Off-ships will require the use of gas canisters to fill the burn chamber. The Horizon can inject gas from the storage tanks within atmospherics. This requires the use of two pumps, and the activation of a valve shown to the right.

- Enable the gas mixer until the desired amount of burn mix has been injected into the burn chamber.

- Disable the gas mixer! Do not leave injection on!

- Ignite the burn mix inside the burn chamber and wait for it to fully burn out.

- On off-ship vessels, some strain on the burn chamber glass at this step is expected.

- Once the fire has stopped and the contents of the tank are 100% CO2, enable hot loop circulation via the Turbine Hot Loop Control console: The recommend configuration is 700L/s input and 1000kpa output.

- The higher you put the output, the more power it generates. Raise as necessary. Keep in mind that this will also lead to the burn chamber cooling down faster.

WARNING: If you feel the burn mixture is going to break the glass or the burn chamber walls, lower the blast doors and vent the chamber immediately! Off-ship vessels have a portable generator in the back if the turbine runs out of fuel, or another mishap occurs.

Turbine Design

While the layout of the turbine may change from ship to ship, the basic concept remains the same. A turbine is made up of X parts: Burn chamber, hot loop, cold loop, cooling array, TEG, connectors.

The burn chamber is, as you might expect, where the burn mixture is ignited to produce useable fuel. This chamber can vary in size but requires a few basic elements. It needs an injector to inject the burn mixture into the chamber, a vent to bring the hot fuel into the hot loop, a second injector to cycle back the hot loop gas, and blast doors for emergency venting. Some burn chambers may have glass viewing ports, but they're not inherently required. Often times, a sensor is present to display temperature, mixture contents, and chamber pressure to a console on the user.

The hot loop is where the fuel is help from the burn chamber. This loop exits the burn chamber, enters into one of the inlet ports on the TEG, exits out the exhaust port of the TEG, and re-injects into the burn chamber. The ports on the TEG must be across from each other or else the cold and hot loops would be mixed and remove the heat imbalance that causes the TEG to function. Beware that this loop by its nature operates at much higher temperatures and pressures than any other loop and is the most likely to fail if the pressure is too high. If the temperature and pressure become too high, open the emergency cold loop to hot loop valves. This will instantly lower the temperature in the hot loop and open it to the cooling array. This will stop most power production from the turbine.

The cold loop is, as expected, where the cold gas is. Much like the hot loop, it connects to an inlet and exhaust port on the TEG. They must be across from each other. Unlike the hot loop, the cold loop connects to the cooling array. This allows the heat transferred into the cold loop from the hot loop to be emitted into space, which reduces the temperature of the cold loop gas, and increases the heat transfer in the TEG.

The cooling array is similar to the Supermatter Reactor's cooling array. It is a loop of pipes that radiate heat into space and reduce the temperature of the gases within its pipes. Unlike normal pipes, which mechanically act like insulated piping, cooling pipes have a much higher surface area and no insulation, allowing for greater heat removal.

The thermoelectric generator (TEG) is the machine that converts heat in gases to electricity. Rather than operating via high-pressure steam turning an internal turbine, the TEG works through heat transfer between two gas loops. The greater the heat difference, the more electricity produced. It is the exact same machine utilized by the Supermatter Reactor.

Connectors are the ways in which gas is introduced into the turbine system. The Horizon, uniquely, has a direct connection between the burn chamber and its gas storage, however other vessels must use gas canisters to inject fuel into the system, or gas into the cold loop. The burn chamber connectors require an omnimixer to achieve a proper ratio of oxidant to hydrogen. The cold loop, however, does not require any particular mixture.

Turbine Theory

See also: Guide to Atmospherics

At a fundamental level, the turbine engine is simply what happens when you combine the combustion chamber of the thrusters and attach it to a TEG from the Supermatter engine. This gives us a look into how it works and lessens the legwork for describing the theory of how this engine works.

The simplified process is this: Burn a gas mixture to produce superheated CO2 -> circulate CO2 in hot loop -> circulate cold gas in the cold loop -> temperature difference between hot/cold loops generates voltage in TEG

But first, there is something key to understand. The Turbine engine is not, by technicality, a turbine generator. Turbine generators work through pushing high-pressure fluid through turbine fan blades causing rotary motion and driving a generator unit. The TEGs do not operate (entirely) off of this principle. They operate using temperature differences between two ends of the generator. Through the Seebeck effect (which is NOT modeled in the mechanics), voltage is generated. Now, the TEGs mechanically are a black box in terms of power generation. What this tells us, however, is how the turbine works.

The Hot Loop

See also: Guide to Thrusters/Combustion and Gasses

Much like the thrusters, the turbine generator operates via combustion. The thrusters use this to increase pressure to generator more force when pushed out of the thruster banks. Meanwhile, the turbine uses combustion to superheat gas for the aforementioned temperature difference. The end effect for both systems is the same. The limiting factor is the pressure chokepoints in the system, typically at vents, pumps, and valves. Given pressure is directly proportional to temperature, the turbine similarly wants higher pressures in the system.

So, what do we need for combustion? Fuel, oxygen, and heat. Heat is easy. The igniter provides the initial heat, and the rest is maintained by the combustion itself. Below are the fuels and oxidizers available on the Horizon.

Fuels

![]() Phoron (Ph). Has a molar heat capacity value of 200, and a molar mass of 0.405 kg/mol.

Phoron (Ph). Has a molar heat capacity value of 200, and a molar mass of 0.405 kg/mol.

![]() Hydrogen (H2). Has a molar heat capacity value of 100, and a molar mass of 0.002 kg/mol.

Hydrogen (H2). Has a molar heat capacity value of 100, and a molar mass of 0.002 kg/mol.

Oxidizers

![]() Oxygen (O2). Has a molar heat capacity value of 20, and a molar mass of 0.032 kg/mol.

Oxygen (O2). Has a molar heat capacity value of 20, and a molar mass of 0.032 kg/mol.

![]() Nitrous Oxide (N2O). Has a molar heat capacity value of 40, and a molar mass of 0.044 kg/mol.

Nitrous Oxide (N2O). Has a molar heat capacity value of 40, and a molar mass of 0.044 kg/mol.

Products

![]() Carbon Dioxide (CO2). Has a molar heat capacity value of 30, and a molar mass of 0.044 kg/mol.

Carbon Dioxide (CO2). Has a molar heat capacity value of 30, and a molar mass of 0.044 kg/mol.

The choice in fuels and oxidizers largely boils down to choosing between phoron and hydrogen. Phoron will burn hotter than hydrogen. This is as a result of its heat capacity; how much heat energy it can store before the temperature raises. Phoron, then is a much better fuel than hydrogen. The issue, however, is phoron is rare and VERY expensive. It's recommended to stick with hydrogen for burn mixes.

Oxidizers, in this case, work practically the same. There may be some minor variations in performance. Their goal is entirely to produce oxygen for the combustion process. Finally, we have the product: Carbon dioxide. Regardless of what components are used in combustion, the result is always CO2. This is a fact of the game mechanics, even if it is scientifically dubious. Thankfully, the temperature of CO2 is all that matters in this system. The hotter the combustion burned, the higher the CO2 temperature, the more performance from the TEG.

Earlier in the process, a ration was mentioned. 40% fuel to 60% Oxidant. This is, essentially, the golden ratio in combustion that leaves no fuel or oxidants remaining. There is a lot of math behind this ratio, and further details on the numbers behind each ratio increment, that can be found on the Thrusters guide here. The short version is that the 40%/60% ratio maximizes the burn temperature, leaves no fuel or oxidants remaining, and is the most efficient ratio available. Seeing as we care mostly about the temperature of the system, this ratio is best left as it is.

There is a safety note remember about this whole process. Walls and glass only begin to take damage and melt if there is heat and fire. If there is no fire, the walls and windows take no damage. This leaves us with two options: Burn a less efficient mixture to remain below the 6000K limit of the walls or prevent the combustion process from continuing. This is why it is mentioned to turn off the injectors before firing the combustion chamber. The burn mix will combust, all of the oxidizers and fuel will be consumed, the fire will die out, and we are left with a superheated gas as a result. In theory, a less efficient mixture can be used, and the combustion process can continue as long as desired.

The Cold Loop

See also: Supermatter Reactor/Coolant

The cold loop is a much simpler system compared to the hot loop. It is made of 2 components: coolant gas and cooling array. The only major question here, then, is the heat capacity of the gas being used. Since temperature difference is what drives the TEG to operate, we want to reduce the increases in the temperature of the cold loop as much as possible. The higher the heat capacity, the better the cold loop performance. This is simply due to heat capacity's function in a gas. The more capacity the gas has, the more heat energy it can absorb before raising in temperature. Once it meets its heat capacity, it rises in temperature. For this reason, the cold loop shares the same fuel options with the hot loop: Phoron and hydrogen.

The only other major item of note is the cooling array. This is the best passive method to reduce the temperature in the loop. The longer the cooling array, the better the cold loop performance. There are other methods of reducing the loop's temperature, such as gas cooler. These, however, consume power. Add too many coolers, and it will consume all of the power being produced by the system.

Improvement

See also: Guide to Thrusters/Modifications and Experimentation

The turbine is a relatively limited engine model. It functions reliably, and produces consistent power, but it is limited by the same metrics as the Supermatter reactor AND the thrusters. However, this also gives us a view into where the turbine can improve. The less obvious area is cooling. The cold loop will naturally rise in temperature over time, so improving the cooling method of the system, or raising the heat capacity of the loop, is a simple method to improving engine performance.

The more obvious area of improvement is system pressure. Much like the thrusters, every connection and fixture on a pipe network has limiting pressure. This maximum is 15000 KPa across all fixtures, whether they be pumps or vents. Similarly to the thrusters, there are ways around these limitations. You can find more details on that here.

Note: This guide does not go into the gritty details of each process and concept. The turbine is, at its essence, the combination of 2 pre-existing systems which have far more details and math present on their respective pages. For brevity purposes, those pages are linked. It is highly recommended to read the links above if you wish to know more behind the atmospheric systems.